For aerosol consumers, the actuator is often the most overlooked part of the product packaging. While they recognize the actuator is the component that dispenses the product, not many are aware that the actuator also controls the fineness of the spray, the amount of product that is dispersed and even how the product is applied.

For aerosol consumers, the actuator is often the most overlooked part of the product packaging. While they recognize the actuator is the component that dispenses the product, not many are aware that the actuator also controls the fineness of the spray, the amount of product that is dispersed and even how the product is applied.

Because the actuator controls the nuances of how a product is dispersed – from the length of the spray to the size of the mist and how the can is held – the actuator can make all the difference in an end user’s experience with a product. Given this, there’s a lot to consider when developing the actuator since it controls so much of the function and experience.

To get the best possible result for your specific product and application, here are five actuator design factors to consider:

1. End Use/Application

Aerosol dispensers are used for a broad array of products, from Home & Garden to Beauty & Personal Care products. The best place to start in the design process is with the end use in mind. For instance, will the consumer use the actuator to spray product toward herself – and more specifically, is the application meant to be for the entire body, or just a specific area like their face or underarms? Will the product be used on a surface, or sprayed into the air? What area of coverage is expected – will the consumer want a targeted spray, or will the mist need to cover a larger area? In each of these scenarios, there is an actuator design that is best suited for each application.

2. Duration of Use

Another important factor is the duration of the spray. Quick-targeted sprays are best for things like deodorant application. However, a consumer may want the spray to have a longer duration if she were applying sunscreen all over her body. A much longer extended spray would be better suited for applying paint or a spray lacquer for finishing a woodworking project. Push-button actuators work best for quick, targeted applications, but for products that need a longer spray duration and larger coverage areas, a trigger actuator is more effective.

3. Ergonomics

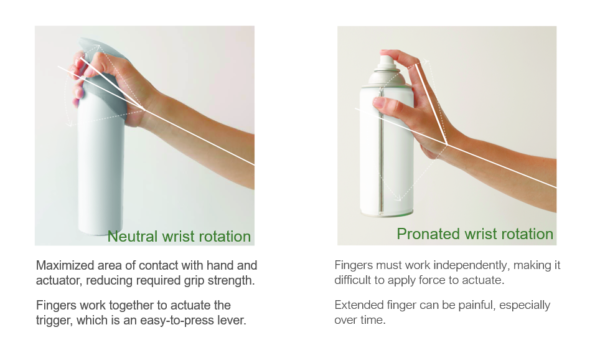

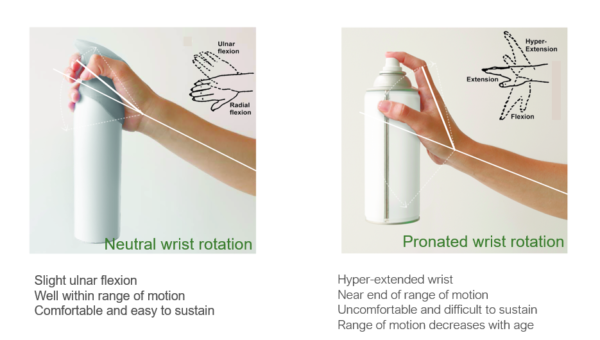

The end use, application and duration of spray taken together play an essential role in determining the ergonomics of the actuator. The ergonomics are designed with those factors in mind, as the end motion dictates how the user should hold the actuator and the most comfortable and effective position to achieve the desired outcome. Take for instance a product like air freshener. Historically, air fresheners featured an aerosol can with a push-button actuator that was triggered by pressing down on the spray button with a single finger while using the rest of the fingers and hand to grip the can. Ergonomically, this actuation method requires a pronated wrist rotation, and the fingers must work independently, making it difficult to apply force to actuate the product and hold the can at the same time.

Taking this into consideration, we evolved the air-freshener experience into one that allows for a more comfortable positioning of the hand by moving to a trigger-spray actuator. The trigger-actuated aerosol allows for a maximized area of contact between the hand and actuator, reducing the grip strength needed to disperse the product and allowing the fingers to work together to actuate the trigger. Additionally, we have found that integrating the actuator to the can by adding an elongated skirt allows for better grip and a gives a more premium look and feel to the overall product.

Differentiation through ergonomics: push button vs. trigger-actuated:

Range of motion for push button vs. trigger-actuated aerosols:

4. Can Size

The size and shape of the aerosol can should also factor into the actuator decision. Short and narrow cans, because of their smaller size and lighter weight, can more easily be gripped while actuating and; therefore, benefit from the simple button-style actuator as pictured above. Conversely, taller and wider cans which are bulkier to hold are better suited for trigger-style actuators.

5. Brand Differentiation

And finally, the actuator design impacts the overall look and feel of the end product. Design cues like color, shape and trigger style can signal price point and product quality to consumers. Push-button actuators are standard and ubiquitous, which signals a lower-cost, basic product to the end customer. Placed on a shelf next to an aerosol product with a trigger or lever actuator that’s integrated to the can and features a custom shape, consumers perceive a higher-quality product that commands a premium price point over the standard button actuator. In fact, by switching to a premium aerosol actuator, one Silgan Dispensing customer was able to command a 123 percent increase in retail price point over their standard push-button actuator aerosol.

Actuators are the workhorse of aerosol products. Not only are they the part of the aerosol that consumers interact with the most, but they also are what consumers rely on to disperse the product to get the job they need done. Actuators can impact a consumer’s experience with and perception of your product from the time they see it on a store shelf up until the last spray of product. Factoring these five considerations into your actuator selection decision will go a long way toward achieving the consumer experience your brand is aiming for, and ultimately, whether or not your customer will make a repeat purchase.